迅 智 光 学

FASTWISE OPTICS

PRODUCT CENTER

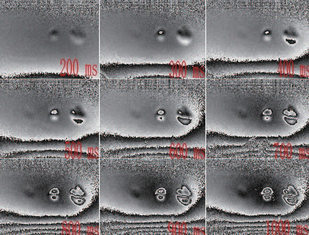

航空复合材料激光无损检测仪,以自主研发激光数字剪切散斑干涉计量技术为基础,结合合材料缺陷识别技术,应用在航空部件如复合料的制造和检修行业,实现非接触、全面、快检测各种复合材料的缺陷(如分层、裂纹、脱、空隙、冲击损伤及其它形式的缺陷等)。

The Aviation Composite Laser Non-Destructive Tester,developed based on proprietary laser digitalshearography speckle interferometry technology integrated with composite defect recognitiontechnology,is applied in the manufacturing and maintenance of aerospace components such ascomposite material parts.This system enables non-contact,comprehensive,and rapid detection ofvarious composite material defects,including delamination,cracks,debonding,voids,impact damage,and other forms of defects.

航空复合材料激光无损检测仪

Laser nondestructive testing instrument for aviation composite materials

航空复合材料激光无损检测仪,以自主研发的激光数字剪切散斑干涉计量技术为基础,结合复合材料缺陷识别技术,应用在航空部件如复合材料的制造和检修行业,实现非接触、全面、快速检测各种复合材料的缺陷(如分层、裂纹、脱粘、空隙、冲击损伤及其它形式的缺陷等)。

Aerospace composites nondestructive laser detector, self-developed laser interferometry digital shearography, combined with the composite defect recognition technology, such as in the aerospace composite member manufacturing and service industries, non-contact, full, rapid detection of various defects in the composite material (e.g., delamination, cracks, debonding, voids, impact damage and other forms of defects, etc.).

基于激光散斑干涉技术,针对航空复合材料,通过真空加载或热加载的无损非接触方式,进行高灵敏度的变形检测,以检测航空复合材料是否存在脱开现象。

Based on laser speckle pattern interferometry for aerospace composites, non-destructive non-contact manner by vacuum thermal loading or loading, deformation detection with high sensitivity to detect whether the phenomenon disengage aerospace composites exist.

联系电话:+86-20-89627989

邮箱:jacky@fastwise.com.cn

联系地址:广州市海珠区工业大道北132号之三十栋101

网站: www.fastwise.com.cn

MESSAGE

如果您对我们有什么建议、投诉、需求,可以通过留言告诉我们,

我们会在**时间了解并及时与您联系。

迅 智 光 学

FAST WISE OPTICS