迅 智 光 学

FASTWISE OPTICS

PRODUCT CENTER

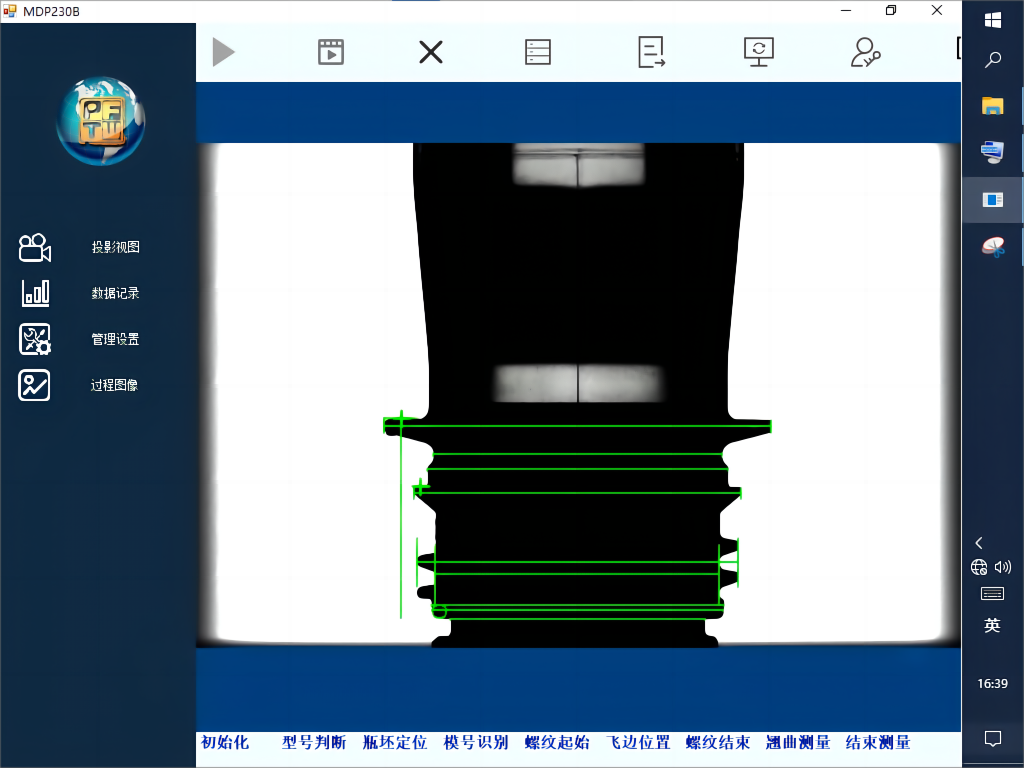

MDP230B瓶坯测量仪,专为5升至20升瓶坯的测量进行量身订制,可测量直径≤64mm,可测量高度≤230mm。提供瓶坯全尺寸测量,包括飞边、翘曲度、字符识别、壁厚差测量。

瓶坯测量仪-MDP230B

FAST WISE OPTICS

Preform Measurement Device

仪器采用光学多镜片分段成像原理设计,通过多段平行光获取轮廓图像,并搭载特殊设计的镜头与光源来提取图像轮廓,以确保轮廓无变形,并保障测量精度。MDP系列仪器能对瓶坯进行自动定位,并自动测量瓶坯的各种尺寸数据,其中包括瓶坯的飞边、翘曲度及壁厚差。同时,它能自动识别并记录瓶坯上的模腔号,并将测量数据自动上传至企业的数据管理平台。

The instrument is designed by the principle of optical multi-lens segment imaging, obtaining the contour image through multiple segments of parallel light, and equipped with specially designed lens and light source to extract the image contour, to ensure that the contour is not deformed, and ensure the measurement accuracy. MDP series instruments can automatically locate the blank and automatically measure the various dimensions of the blank, including the flying edge, warping degree and wall thickness difference of the blank. At the same time, it can automatically identify and record the mold cavity number on the bottle blank, and automatically upload the measurement data to the data management platform of the enterprise.

技术优势/Technological superiority

卡坯头通过伺服电机带动旋转,对瓶坯的固有特征点进行定位,实现所有瓶坯达到标准化测量;

The card blank head is rotated by the servo motor to locate the inherent characteristic points of the bottle blank, so as to realize the standardized measurement of all the bottle blank;

具备远程控制功能,便于仪器维护;

With remote control function, easy to facilitate instrument maintenance;

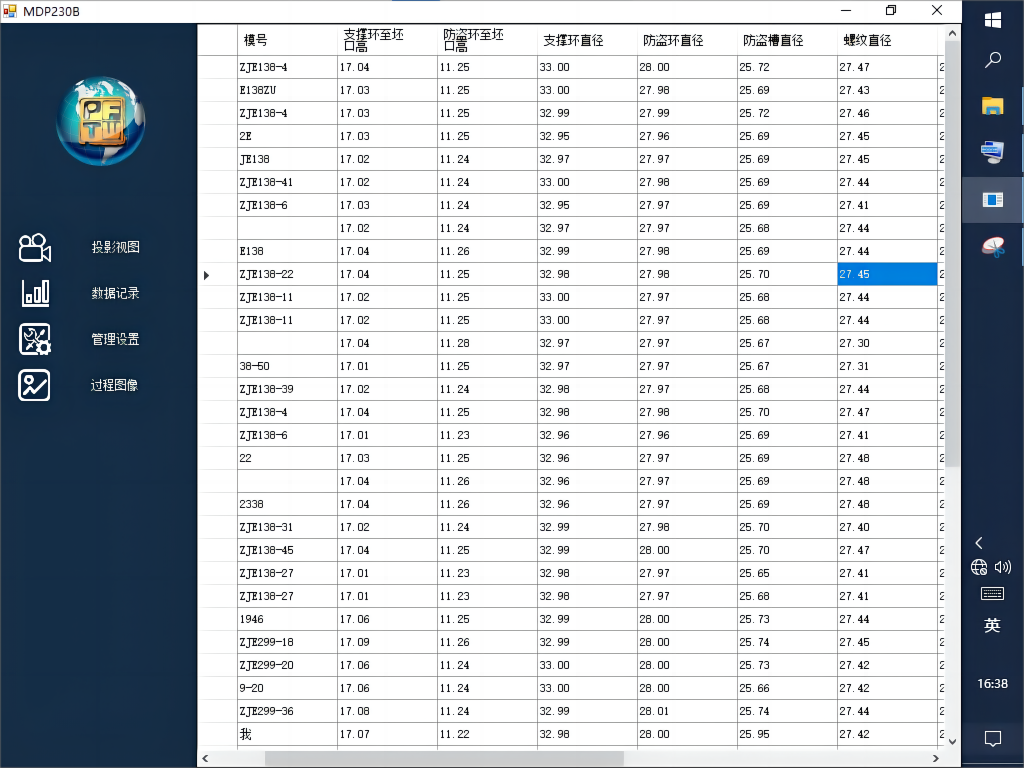

测量数据表格化呈现,可一键式数据导出或打印;

Measurement data is tabulated, which can be exported or printed with one click;

通过系统学习后,可自动识别记录模号字符;

After the system learning, the recording mode character can be automatically identified;

独特的光源设计,可实现坯身壁厚差的测量;

Unique light source design, can realize the measurement of the blank wall thickness difference;

精准的定位方式,可测量瓶坯飞边;

Accurate positioning mode, can measure the bottle blank fly edge;

瓶口倒插方式,更精准测量瓶坯翘曲度;

Bottle mouth inverted method, more accurate measurement of bottle blank warping;

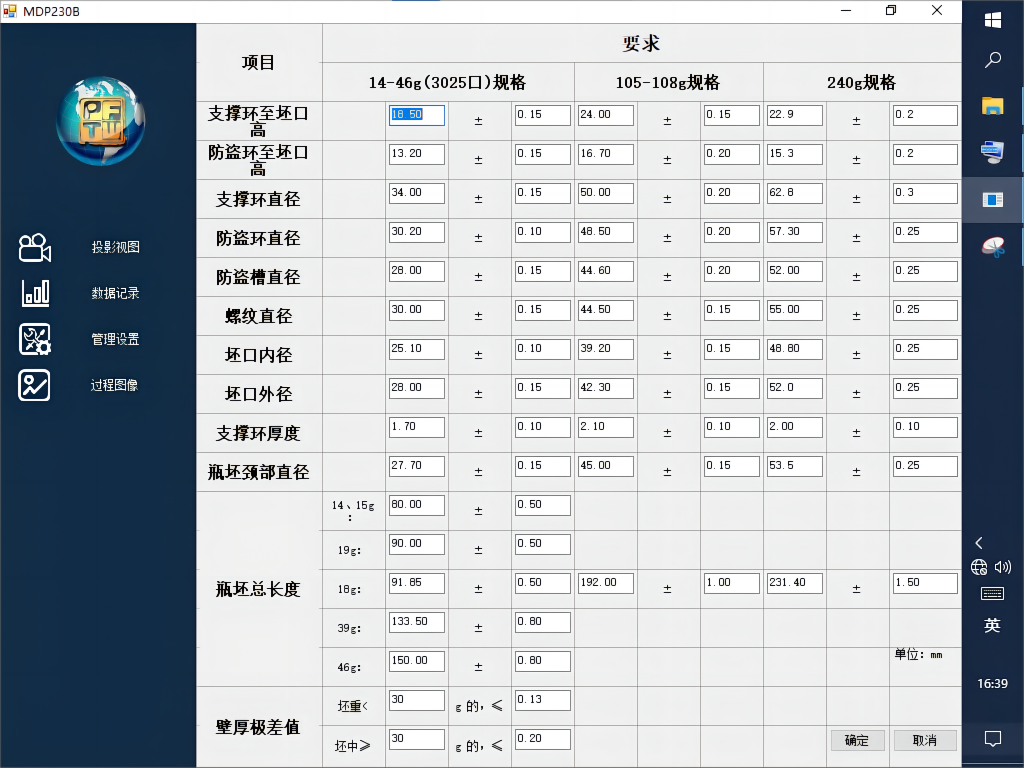

操作界面清晰简洁,自由设置测量数据参数;

The operation interface is clear and simple, freely set the measurement data parameters;

软件系统内置多种标准瓶口测量模块,包含瓶口为1810、1881、29/25、30/25、28、38等测量模块;系统通过自动识别瓶坯类别来智能选择不同的测量模块;

The software system has a variety of standard bottle opening measuring modules, including 1810,1881,29 / 25,30 / 25,28,38, etc. measuring modules; the system intelligently selects different measuring modules by automatically identifying the blank category;

测量软件可设置多种工作模块,满足日常测量模块、月测量模块,从而提升更高的检测效率;系统设置操作员登录界面,每一项测量数据均具备可追溯性;

The measurement software can set a variety of working modules to meet the daily measurement module and monthly measurement module, so as to improve the higher detection efficiency; the system sets the operator login interface, each measurement data has traceability;

局域网组建,内网浏览数据更便捷安全;

LAN establishment, Intranet browsing data is more convenient and secure;

互联网协议(mqtt),支持有偿接入云服务器管理系统,包括检测数据归集、数据图表式呈现、生产模腔超标统计并提示用户关注模腔磨损、定制化QC集团管理、支持实验室其他仪器的云数据服务。

Internet protocol (mqtt) supports paid access to cloud server management system, including collection of data detection, data chart presentation, production of mold cavity exceeding statistics and prompting users to pay attention to mold cavity wear, customized QC group management, and support cloud data services for other instruments in the laboratory.

互联网服务还包括系统备份、数据备份、仪器测量时异常产品的图片采集、仪器测量时故障图片采集、软件升级。

Internet services also include system backup, data backup, picture collection of abnormal products during instrument measurement, fault picture collection during instrument measurement, and software upgrade.

重复精度/Repeat Accuracy

测量项目 Inspection Detals | MDP180P | MDP180C | MDB230P |

"A"锁环直径 Tamper Band Dia. | ±0.01mm | ||

"B"防盗环直径 PP Band Diameter | ±0.01mm | ||

“C"螺纹高度 Thread Projection | ±0.01mm | ||

"D"锁环高度 Distance Tamper Band | ±0.01mm | ||

"E"瓶口外径 Neck Dia. | ±0.01mm | ||

“F"飞边 Flash | ±0.01mm | ||

“G”防盗环处间距 PP Band Clearance | ±0.01mm | ||

“H”螺纹末牙位置 Distance Thread End | ±0.01mm | ||

“I”瓶口内径 Inner Mouse Dia. | ±0.02mm | ||

“L“瓶坯总高 Total Height | ±0.05mm | ||

“O”支撑环厚度 OD Band Thickness | ±0.01mm | ||

“R”瓶口外圆弧度 Seal Radius | ±0.01mm | ||

“S”螺纹起牙位置 Distance Thread Start | ±0.01mm | ||

"T" 螺纹顶径 Thread Dia. | ±0.01mm | ||

“U”壁厚差 WT Difference | ±0.03mm | ||

“V”螺纹顶端宽度 Thread Tip Width | ±0.01mm | ||

“W”翘曲度 Concentricity | ±0.05mm | ||

“X“瓶口高度 Neck Ring Height | ±0.01mm | ||

“Y“螺纹角度 Thread Angle | ±1° | ||

“Z”支撑环直径 OD Band Dia. | ±0.01mm | ||

瓶口椭圆度 Neck Ovality | —— | √ | —— |

模具字符识别 Mold nos. recognition | √ | √ | √ |

互联网数据平台 Cloud data management | √ | √ | √ |

联系电话:+86-20-89627989

邮箱:jacky@fastwise.com.cn

联系地址:广州市海珠区工业大道北132号之三十栋101

网站: www.fastwise.com.cn

MESSAGE

如果您对我们有什么建议、投诉、需求,可以通过留言告诉我们,

我们会在**时间了解并及时与您联系。

迅 智 光 学

FAST WISE OPTICS